Innovation : Engineered for Excellence

Fuxiang Group specializes in advanced footwear component innovation.Our patented technologies—covering material science, production processes, and equipment design—support global footwear brands and Tier 1 manufacturers in developing high-performance and more sustainable products with precision and efficiency.

Innovation in Application

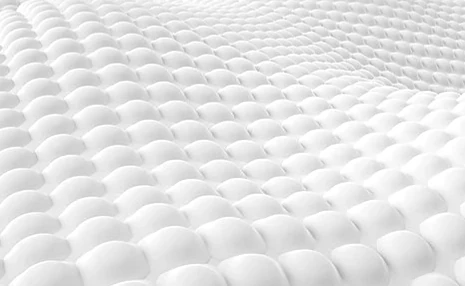

High-Performance Particle Bonding Technology (CN119752153A)

Our Popcorn Foam is developed using a modified bio-based polyol system to enhance moisture vapor transmission, breathability, and abrasion resistance. Designed for athletic and lifestyle footwear, it delivers durable comfort with a responsive underfoot feel.

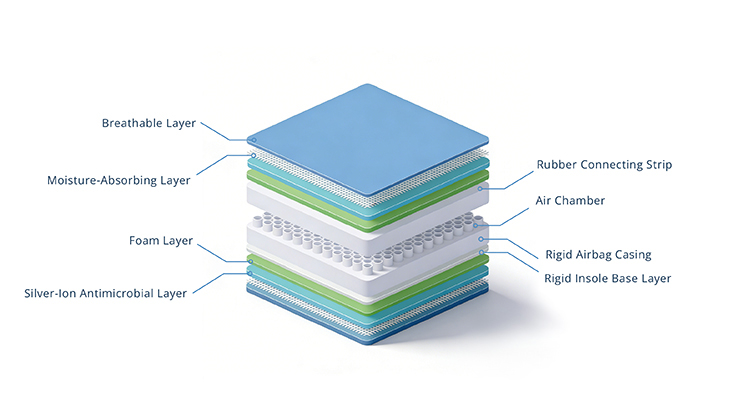

Air-Cushioning Insole Structure (CN220694532U)

This inflatable insole features a multi-layer air-chamber structure that adapts to foot movement, providing targeted cushioning and stability. Integrated antimicrobial treatment and moisture-wicking layers help maintain hygiene and dry comfort during extended wear.

Material Innovation

Precision-Engineered Solutions

Supercritical Foam –

For Peak Performance

For applications where weight efficiency and energy return are critical, our supercritical foam solutions are engineered to meet these performance demands.PulseSport Pro SC75 delivers up to 75% rebound resilience with an ultra-low density of 0.07 g/cm³, making it suitable for performance-driven athletic footwear.

Advanced EVA – Balanced Performance and Value

For applications that prioritize softness, cost efficiency, and stable rebound performance, advanced EVA provides a balanced material solution.EVERYDAY Lite EE28 achieves approximately 60% rebound resilience, delivering reliable comfort and near top-tier performance at a competitive cost for volume-oriented footwear programs.

Bio-Based PU – Lightweight and Sustainable

When sustainability, dimensional stability, and lightweight construction are key design requirements, bio-based PU offers a durable material platform.PowerFrame Bio 50% Lite combines a low density of 0.18 g/cm³, a compression set of approximately 10%, and 50% bio-based content, supporting lightweight designs for orthotic inserts and sustainability-focused footwear collections.

Advanced Manufacturing Systems

We develop proprietary manufacturing equipment to support consistent quality and scalable production:

Precision Injection System (CN220681416U)

A reinforced guard structure protects injection nozzles, reducing operational risk and supporting stable, repeatable output.

Automatic Printing & Pressing (CN220700781U)

A reinforced guard structure protects injection nozzles, reducing operational risk and supporting stable, repeatable output.

Thermoforming with Integrated Cooling (CN221641564U)

Built-in cooling accelerates material setting, helping maintain dimensional accuracy while shortening cycle time.